We Make Clean Air - We Ship WorldWide

CleanAirSolution Blog @ Wordpress

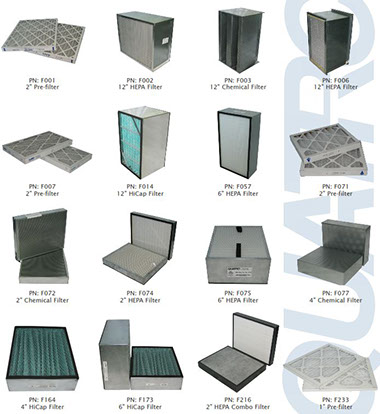

We're Your Source of Genuine Quatro Air Filters and Parts : HEPA Filters, Bag Filters, Dust Pre-Filters, Chemical Odor Filters, Bulk Chemical Media, Motors, UV Light, etc. - Shipped To You Factory Fresh

How often do I have to change my filters?

For filter life each application is completely different. It depends on the materials you are working with, and how often you are creating particulate. For instance in Laser applications the depth you are cutting / engraving, the laser wattage, the type of material you are working with are all factors. Typical applications have the pre-filter being changed approximately every 1-3 months, HEPA filter 6-12 months, chemical filter 6-12 months. This is just a guide as some end users last much longer and some also consume the filters much quicker.

What is a HEPA filter?

HEPA filters, by definition, remove at least 99.97% of airborne particles 0.3 micrometers (µm) in diameter. Some manufacturers use HEPA material in their filters and claim that these are HEPA filters. Quatro Air certifies our filters as HEPA which means that they go through a vigorous testing procedure and meet medical standards for filtration.

HEPA filters are composed of a mat of randomly arranged fibres. The fibres are typically composed of fiberglass and possess diameters between 0.5 and 2.0 micron. Key factors affecting function are fibre diameter, filter thickness, and face velocity. The air space between HEPA filter fibres is much greater than 0.3 μm. The common assumption that a HEPA filter acts like a sieve where particles smaller than the largest opening can pass through is incorrect. Unlike membrane filters, where particles as wide as the largest opening or distance between fibres cannot pass in between them at all, HEPA filters are designed to target much smaller pollutants and particles. These particles are trapped (they stick to a fibre) through a combination of the following three mechanisms:

- Interception, where particles following a line of flow in the air stream come within one radius of a fibre and adhere to it.

- Impaction, where larger particles are unable to avoid fibres by following the curving contours of the air stream and are forced to embed in one of them directly; this effect increases with diminishing fibre separation and higher air flow velocity.

- Diffusion, an enhancing mechanism is a result of the collision with gas molecules by the smallest particles, especially those below 0.1 µm in diameter, which are thereby impeded and delayed in their path through the filter; this behaviour is similar to Brownian motion and raises the probability that a particle will be stopped by either of the two mechanisms above; it becomes dominant at lower air flow velocities

Diffusion predominates below the 0.1 μm diameter particle size. Impaction and interception predominate above 0.4 μm. In between, near the 0.3 μm MPPS, diffusion and interception predominate.

The filter resistance to flow is known as its pressure drop.

What is the Laser Blue Gel?

We are proud to introduce our new breakthrough technology. We call it the LASER BLUE GEL. This sleek blue design is nothing like the regular gasket you may find in other filtration units on the market. Due to it's elasticity, it allows zero bypass to any fumes, odors and VOCs. It's NON toxic and NON porous as well

What are VOCs?

Volatile organic compounds (VOCs) are organic chemical compounds that have high enough vapor pressures under normal conditions to significantly vaporize and enter the atmosphere. Volatile organic compounds are numerous and varied. Although ubiquitous in nature and modern industrial society, they may also be harmful or toxic. VOCs, or subsets of the VOCs, are often regulated.

VOCs may be natural or synthetic. Like organic chemicals in general, there are millions of different compounds which may be classified as VOCs. The compounds the nose detects as smells are generally VOCs. Modern industrial chemicals such as fuels, solvents, coatings, feed stocks, and refrigerants are usually VOCs.

As organic chemicals, VOCs may have health consequences, but this is depending on the specific chemicals that are part of the umbrella definition "VOC". For indoor air purposes, there are long lists of limit values[1] published by German AgBB, French AFSSET, and California EPA ("CREL"). Because they tend toward the gaseous state, management of toxic VOCs is more difficult than with non-volatile compounds. Human exposure to VOCs can be through contact with the solid, liquid, or gaseous forms, inhalation of the gaseous form, or ingestion of the liquid form or solutions containing the VOC.

Because of their health effects, VOCs are regulated in some places. The large number of VOCs combined with their numerous exposure pathways make comprehensive management, discussion or regulation of volatile organic compounds impractical. Instead, subsets of VOCs are regulated by a wide variety of governmental agencies.

What's the difference between brushed and brushless motors?

Brushless blower motors have a higher capacity to move air than brushed motors however do so with less static pressure. Static pressure can be thought of as suction and is measured in inches of water column (wc.). Thus a low suction unit will pull water perhaps 2 inches up a pipe and no more and thus would have a static pressure of 2"wc. High power brushless motors have a maximum measurement of 44"wc. This makes them ideal for applications with VOCs, odors and light loads of dust. Brushed motors on the other hand are measured at 90"wc and are ideally suited to conveying heavier smoke, heavier dust and any type of 'sticky' fume. Not only do the brushed motors have more static pressure but the filters tend to last longer as the motor can continue to 'suck' air through dirty filters that might otherwise reduce the airflow and require changing in a brushless unit. Brushed units are typically less expensive than the brushless units however they do require that the brushes be changed every 500-700 hours. This is a simple procedure that takes approximately 2 minutes and the only tool required is a screwdriver. Demonstration videos are provided for each of our products indicating how to perform this simple procedure. Since there are many advantages to both types of blower motors many of our units are available with either type as an option. If you have any questions or concerns about which type of blower motor is best suited for your application please call us at 1-800-626-0664 in North America or +1 514-364-5538 internationally to discuss it with one of our experts.

Brushless blower motors:

Pros

- The most powerful at moving air, up to 300 CFM

- Require no maintenance

Cons

- Maximum static pressure 44" wc

- Expensive

- Filters require more frequent changes with heavier types of dust.

Differences in filter efficiency (low, medium, high, etc)

1. LOW EFFICIENCY FILTERS

Most Low Efficiency Filters are pad or panel type filters, with average filter efficiency reaching 30%. These filters remove large particles, usually 10 microns or larger. Ideal application is light residential.

2. MEDIUM EFFICIENCY FILTERS

Medium Efficiency Filters can be in the Form of a bag type or box type lifter, with an average efficiency ranging between 40% to 60%. These Medium Efficiency Filters effectively remove particles in the 3.0 to 10.0 microns in range. These filters are usually pleated allowing for a much greater surface area which significantly increases the filter’s longevity while reducing pressure drop.

This filter is usually a flat, large surface pleated filter with an aerodynamic design and superior filtering capacity. The alignment of the pleats ensures consistent airflow through the filter. Its design increases its filtering surface as air passes through the media on each side of the pleats. The larger dust particles are usually trapped at the bottom of the pleats, while the smaller ones collect on the sides.

Medium Efficiency PLEATED Odor Filters

A pleated activated carbon filter has the same Dust removal features as MEDIUM EFFICIENT FILTER mentioned above, however this filter features a flameproof cardboard frame and carbon impregnated filter media, which is laminated and pleated. This filter is the perfect solution to eliminate light odors caused by gases, cigarette smoke, etc.

3. HIGH EFFICIENCY FILTERS

High Efficiency Filters can be in the form of a bag type or box type filter. with an average efficiency ranging between 80% to 90%. These High Efficiency filters effectively remove particles 1.0 microns and larger.

Filter media is made of ultra fine fiber. Aluminum separators between each pleat ensure a longer life to the filter. It can be available in three efficiency levels: 60-65%, 80-85% and 90-95%, 6 or 12-inch thick.

4. HEPA FILTERS

HEPA (High Efficiency Particulate Absolute) Filters are designed to capture sub-micron particles that would tend to pass straight through traditional Ashrae rated ventilation filters. These microscopic particles can come in the form of smoke, powders, aerosols, metal fumes, bacteria, mold and lung spores. HEPA Filters are extremely critical in order to provide a safe working environment where small particulate matter is generated. It is these sub-micron particles that escape the human built-in filtration system and as a result can make their way deep into our lungs where they cannot be expelled, causing long term health concerns. It is For this reason that allergists, asthma specialists and air filtration specialists alike, recommend the use of HEPA filtration to provide healthy environments.

HEPA filters are also used to protect sensitive electronic equipment by introducing extremely clean air over the working

environments. By doing this we reduce the impact that the particulate matter can have on the micro circuitry of today’s

sophisticated machinery. Essentially as electronic equipment becomes smaller it also becomes more susceptible to its’

environment.

All HEPA Filters are rated and tested against the same standard to ensure accurate and reliable ratings from supplier to supplier. Manufacturers use an upstream concentration of D .0. P. (dioctylphthalate) which is an oil commonly used in the plastics industry. The intent is to produce a high concentration of 0.3 micron particulate matter by heating the D.O.P oil to a temperature of approximately 200 C. This air-stream is then introduced and measured upstream of the HEPA filter to establish an inlet concentration. Measuring downstream of the filters using a photometer, removal efficiencies as high as 99.997% can be seen.

High-Tech industries are extremely familiar with the use of HEPA filters in their clean rooms to ensure that essentially all particulate matter greater than 0.3 microns are eliminated. This is essential, to not interrupt their production facility, cause rejects, and minimize poor quality products as a result of air quality. Other applications that rely on the effectiveness of HEPA filtration include medical, pharmaceutical, films, graphic arts, bio-medical/research and the electronics industry to name a few.

5. CHEMICAL FILTERS

HEPA filters and traditional ventilation filters only remove particulate matter and therefore some other means must be employed to treat and remove gases, odors and vapors. A commonly used and readily available product to achieve this goal is activated carbon.

Activated carbon can come in many shapes, sizes and forms. Traditionally raw substrate materials such as coal, wood, peat-moss and coconut shell are thermally processed to produce an air filter quality activated carbon. A Virgin non-impregnated activated carbon is useful in the removal of general volatile organic compounds (VOC's) or hydrocarbons. It’s uses are widespread, and are frequently applied as a general purpose catch all material for non-critical applications.

For more specific and critical gas phase control, activated carbons can also be impregnated with specialty chemicals. This is done to enhance the removal efficiency and capacity for a specific contaminant that is not effectively captured by the virgin non-impregnated activated carbon. Common impregnates include phosphoric acid, sodium and potassium hydroxide. iodine, potassium permanganate and sulfur to name a few.

It is extremely important to realize that there are thousands of different types of carbons available on the market and the appropriate carbon must be selected for the specific application. That is to say that if you have purchased a “BLACK” carbon it is not necessarily what you need. For the novice, making media selections is often the most difficult aspect of the gas-phase filtration design process. Please feel free to contact us at Quatro and use our in-house chemical engineers to evaluate your needs for your specific application.

** Please note: Specifications / Prices Subject To Change Without Prior Notice **